- ATTRACTION of TOYOTETSU

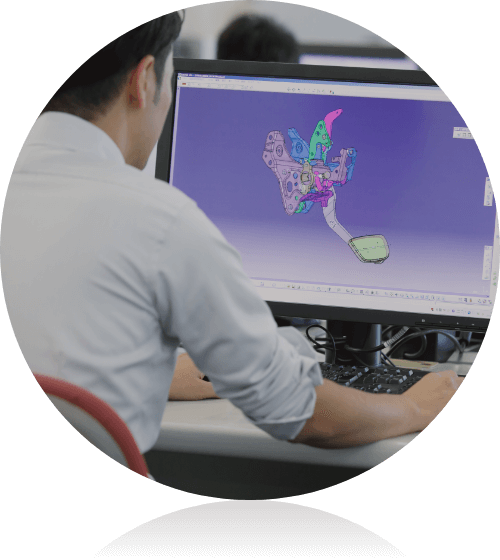

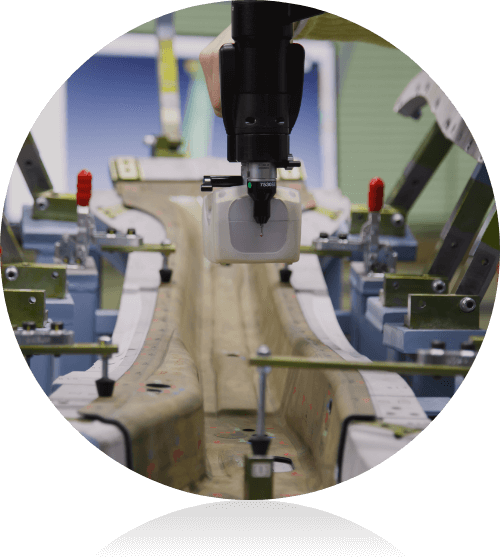

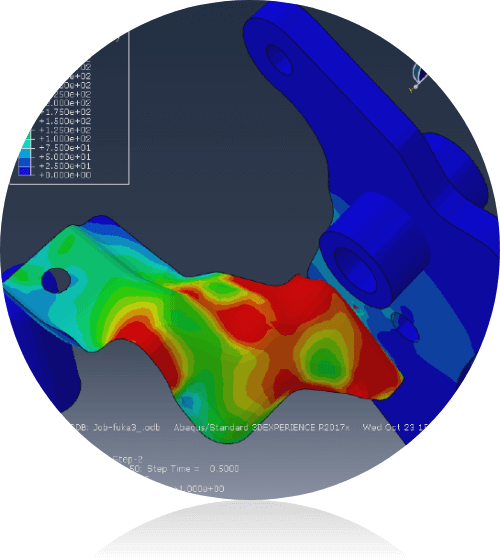

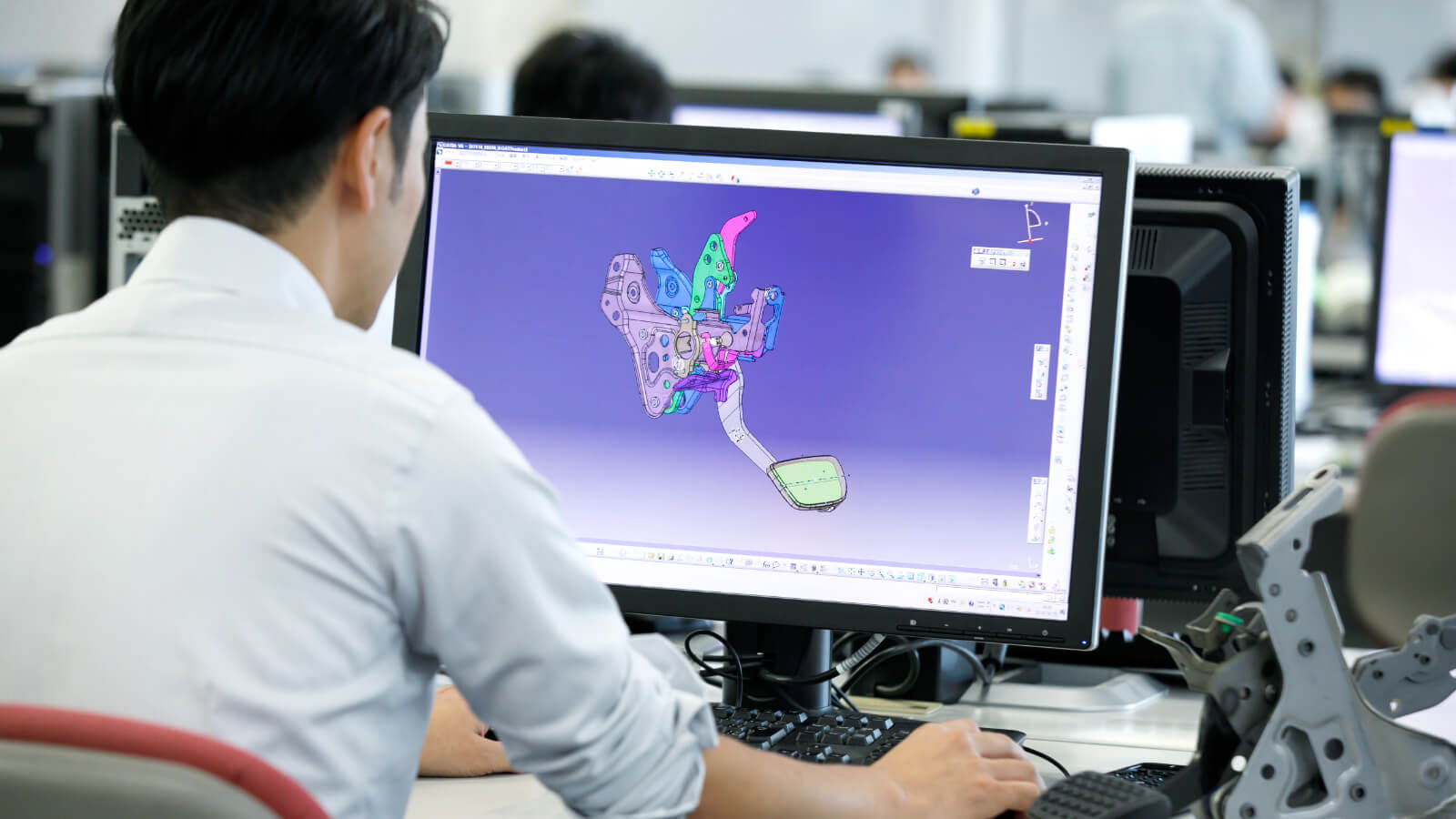

- PRODUCTS & TECH

- NETWORK

- Domestic Bases

- Overseas Bases

- Toyotetsu America, Inc. (TTAI)

- Toyotetsu Mid America, LLC (TTMA)

- Toyotetsu Texas, Inc. (TTTX)

- Fukai Toyotetsu Indiana Corp. (FTIC)

- Y-tec Keylex Toyotetsu Alabama. Inc. (YKTA)

- Toyotetsu Canada, Inc. (TTCA)

- Toyotetsu de Mexico S.A. de C.V. (TTMX)

- Toyotetsu Otomotiv Parcalari Sanayi Ve Ticaret A.S. (TTTI)

- PT. Nusa Toyotetsu (NTC)

- PT. Nusa Toyotetsu Engineering (NTTE)

- Toyotetsu India Pvt.Ltd., (TTIA)

- Toyotetsu India, Auto Parts Pvt.Ltd., (TTID)

- Toyotetsu (Thailand) Co., Ltd. (TTTH)

- Technol Eight Philippines Corp.(TEP)

- Tianjin Toyotetsu Automobile Parts Co., Ltd. (TTAP)

- Guangzhou Toyotetsu Automobile Parts Co., Ltd. (GTAP)

- COMPANY INFO.

- SUSTAINABILITY

- NEWS

- Sitemap

- Privacy Policy

- Site Usage Conditions

- For Internal Use

- Gallery

- CONTACT