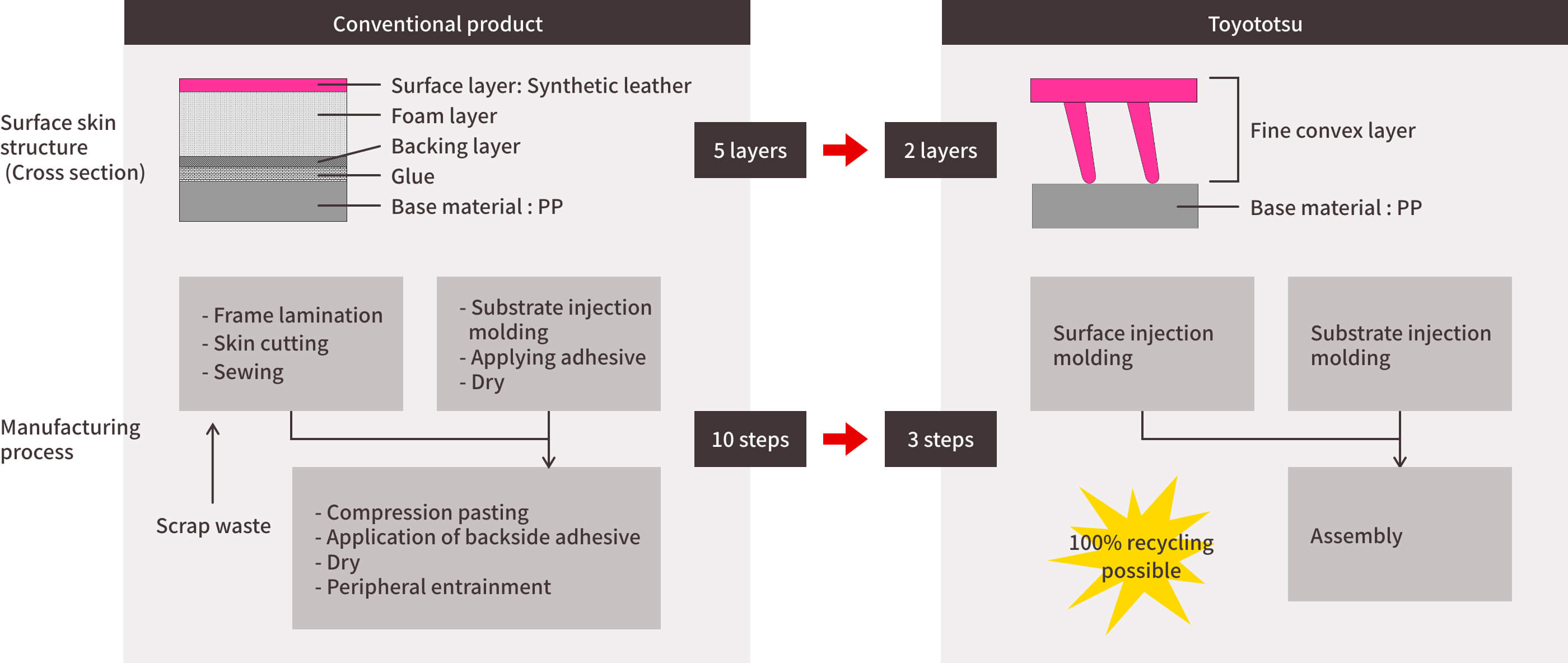

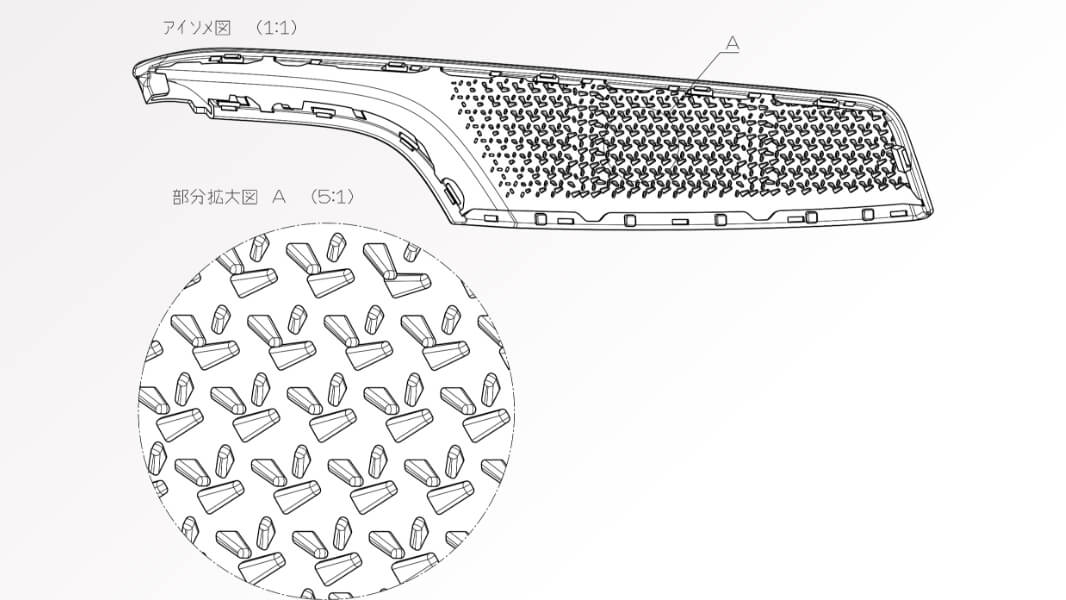

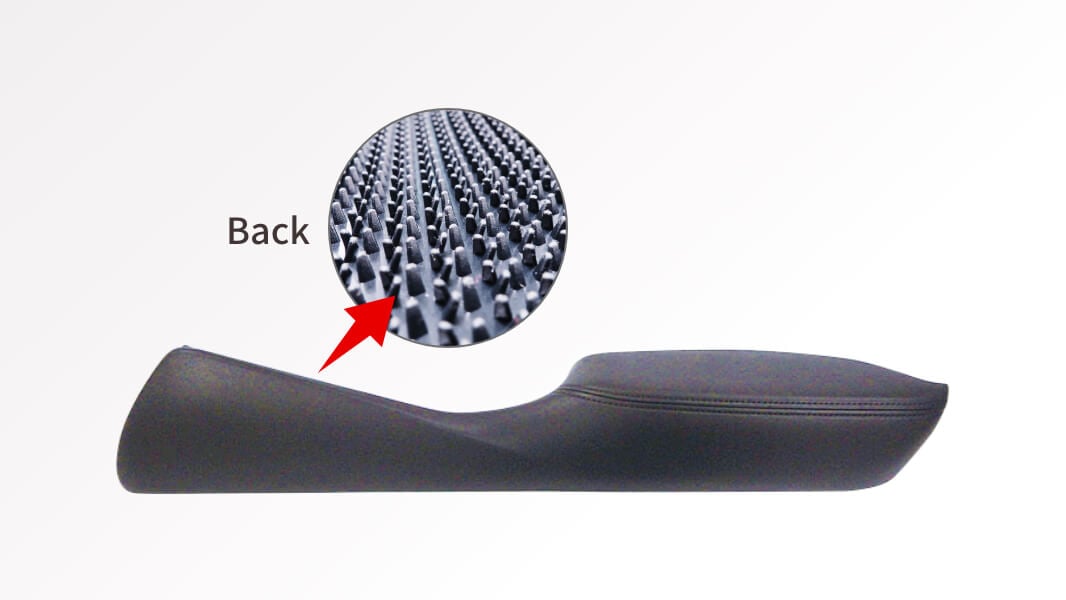

Conventional door arm rests consist of five layers, representing the feeling of touch with urethane in the foam layer, but the shingled parts consist of two layers, molded products and base materials only, as shown in the figure at the top right, representing the feeling of touch with a fine convex shape.

With this structure, the conventional product manufacturing process takes 10 steps, including urethane lamination, skin cutting, sewing, adhesive application, drying, etc., but can be reduced to three steps, namely, injection molding and assembly of the surface layer and the base material, thereby reducing costs.

In addition, we can easily separate the surface layer and the base material even after assembling from conventional products without discarding cut-off materials and without adhesives. This structure is 100% recyclable and environmentally friendly.