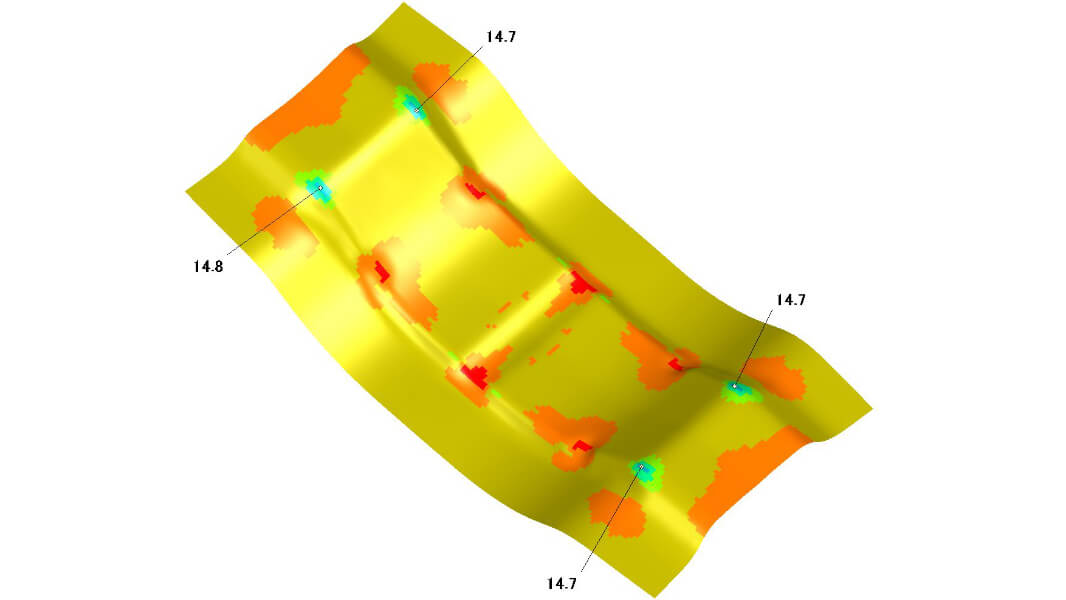

The springback amount (*2) can also be viewed at the same time during the forming analysis.

The higher the yield stress, the greater the amount of springback.Therefore, we must consider the forming process and the construction method in consideration of the springback.

In addition, as the yield stress increases, the forming load required for press working also increases, so die design considering die strength is necessary.

※2 Springback: The phenomenon of returning to the original state when a steel plate is bent by press working