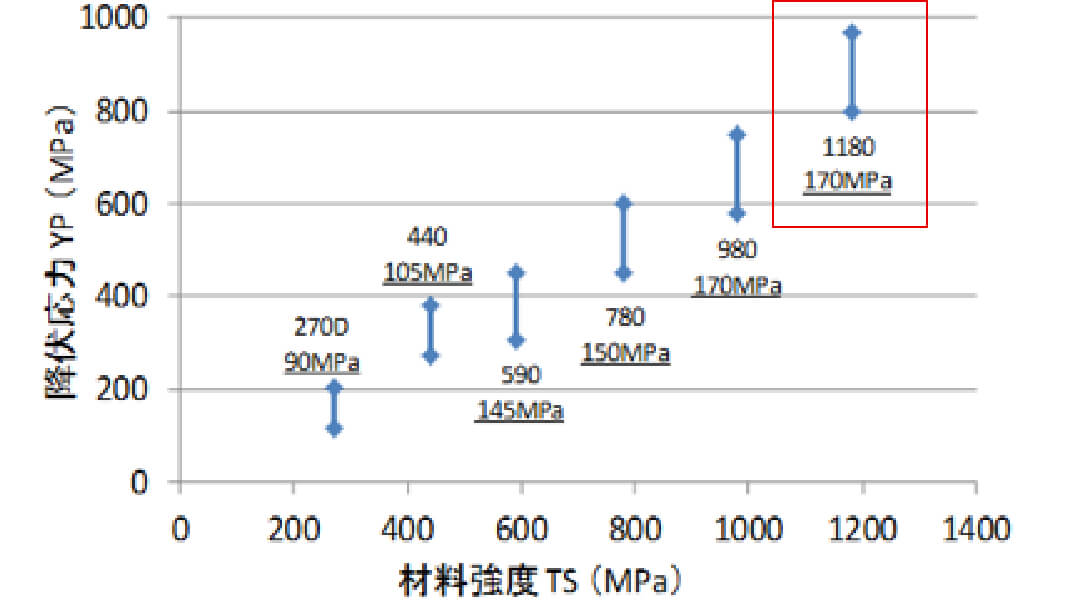

Reducing the weight of the skeleton that makes up the body parts is an essential issue in promoting weight reduction of the car body. For this purpose, we use a steel plate with a tensile strength of 1180MPa, called ultra-high tensile strength material.

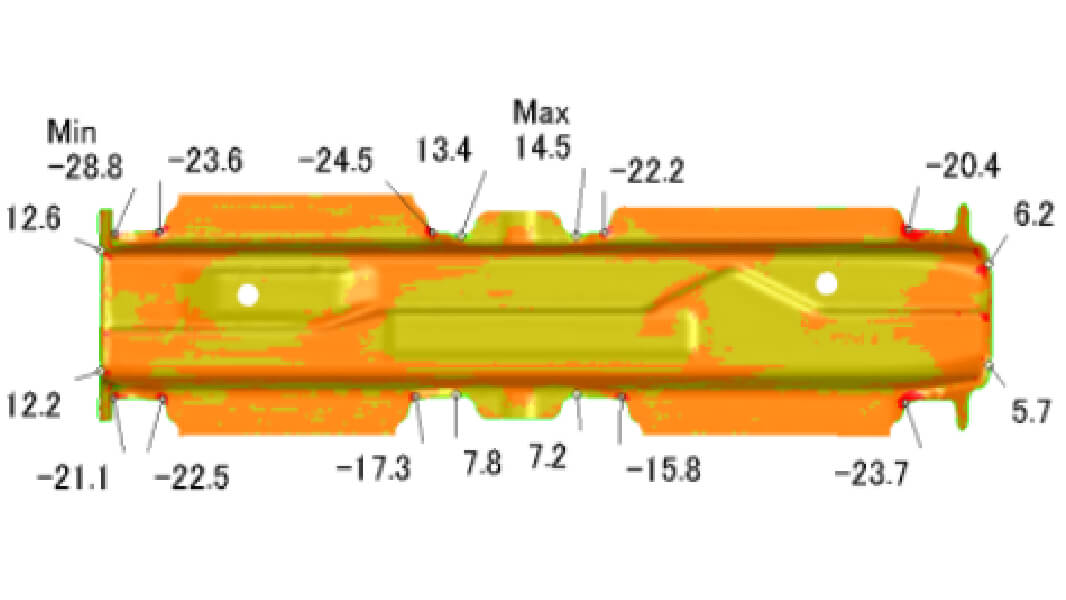

They are used mainly for important parts such as the reinforcement of center pillars, rockers passing under doors, and floor cross running right and left under seats, which are related to riding comfort, such as side collisions, offset collisions, and other safety aspects as well as torsion of the car body and abnormal noise during running.